Leading the transition to high-performance, low-carbon building materials

AusPozz™ Project

The AusPozz™ Project is Zeotech’s flagship initiative aimed at transforming Australia’s construction sector through the production of advanced, low-carbon building materials. The project will establish the country’s first large-scale high-reactivity metakaolin, AusPozz™ manufacturing facility, a high-performance supplementary cementitious material (SCM). The project aims to deliver advanced low-carbon concrete solutions and serve as a key enabler in decarbonising Australia’s built environment.

Project Highlights

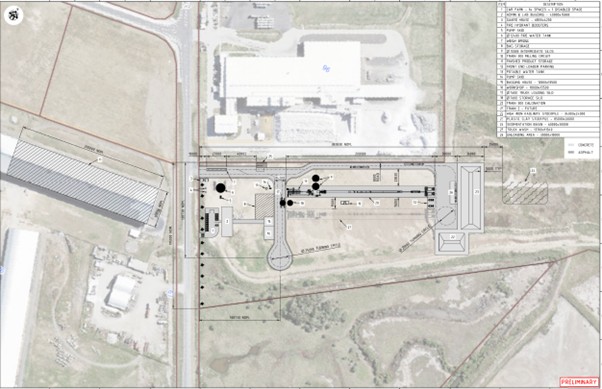

- Location: the planned AusPozz™ manufacturing facility will be located at the Port of Bundaberg, Queensland, with high-purity kaolin ore supplied from the Company’s Toondoon Kaolin Project. The Port offers an ideal strategic location, providing economical and lower-carbon logistics to the Sydney and Melbourne construction markets, while also enabling efficient access to international shipping routes.

- Scale: Designed for an initial calcination train of 300,000 tonnes per annum of AusPozz™ production, supported by a 20-year mine life. The project also allows for a second kiln to be added, doubling production capacity.

- Economics: In June 2025, the Company completed a Preliminary Feasibility Study (PFS) that confirms a strong business case, with forecast net cash flow of $1.014 billion, an NPV of $406 million, an IRR of 42%, and a payback period of just 2.1 years.

- Commercial traction: In September 2025, the Company secured a rolling five-year, $200 million direct shipping ore (DSO) kaolin offtake agreement with Jiangsu Mineral Sources International Trading Co. (MSI), underpinning the first stage of the AusPozz™ Project. In addition, the Company is collaborating with Holcim Australia, part of the world’s largest sustainable building materials group, under an MoU signed in October 2024 to accelerate the commercialisation of AusPozz™ in low-carbon concrete applications.

Why AusPozz™ Matters

Concrete is the world’s most widely used building material, yet traditional cement production remains one of the largest sources of carbon emissions. AusPozz™ offers a one-for-one cement replacement, delivering:

- Significant carbon reduction: Train 1, with a nameplate capacity of 300,000 tonnes per annum, has the potential to avoid up to 229,800 tonnes of CO₂-e emissions annually through its use as a cement binder substitute in concrete. This is equivalent to removing more than 53,000 cars from the road or planting 3.5 million trees each year.

- Superior performance: Independent trials have confirmed that AusPozz™ enhances concrete strength, reduces shrinkage and the risk of concrete cancer, and improves durability compared with conventional SCMs. By enabling both substitution and reduction of total cement binder while still achieving required strength specifications, AusPozz™ offers the potential to lower the overall cost per cubic metre of concrete.

- Jobs & community impact: Creation of more than 140 skilled roles across mining, logistics, manufacturing, and administration, delivering long-term economic benefits to regional Queensland.

- Alignment with Net-Zero goals: Supports Australia’s climate commitments while meeting growing demand for low-carbon building and infrastructure.