Lower emissions, stronger concrete: The AusPozz™ Advantage

AusPozz™ high-reactivity metakaolin

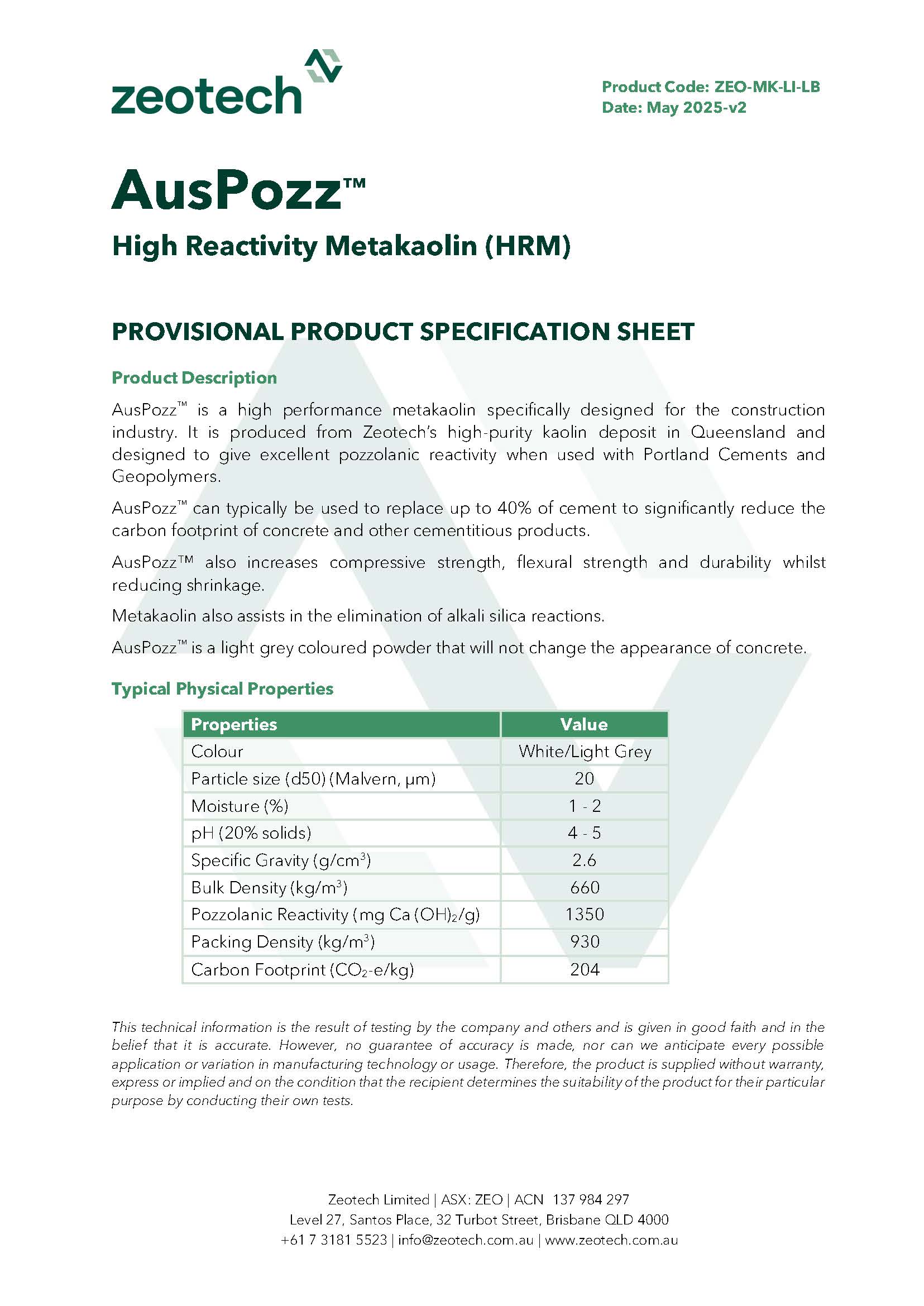

AusPozz™ is a high-performance metakaolin for use in low-carbon concrete and as a manufactured pozzolan it is approved for use in Australian concrete standards as a Supplementary Cementitious Material (SCM).

AusPozz™ is produced from Zeotech’s high-purity Toondoon kaolin deposit in Queensland and designed to give excellent pozzolanic reactivity when used with Portland Cement and Geopolymers. It can significantly reduce the carbon footprint of concrete and other cementitious products while providing a range of performance advantages.

Independent carbon footprint evaluation of AusPozz™ confirmed approx. 204kg/tonne, which is 79% less than Ordinary Portland Cement (OPC) binder.

Background

Metakaolin is a semi-calcined kaolin (produced typically at temperatures between 650°C and 750°C). Pozzolanic materials, like AusPozz™, have been utilised in building and construction for their technical benefits for over 2000 years.

The recognised performance benefits from using pozzolans in concrete are:

- Elimination of alkali-silica reaction (concrete cancer)

- Increased durability and compressive strength

- Reduced water absorption

- Reduced chloride penetration

- Increased sulphide resistance

- Efflorescence control

- Increased flexural strength

- Increased abrasion resistance

The conventional manufacturing process for high-reactivity metakaolin is expensive and produces a relatively high-carbon product, restricting its use to high-performance concrete applications. Calcined clay (low-reactivity metakaolin) is widely used in concrete globally to reduce embodied carbon, but its effectiveness and potential market are limited by its performance. Zeotech’s ultra-high purity Toondoon kaolin feedstock enables a lower-cost flow sheet to produce AusPozz™, which is specifically designed for:

- Low embodied carbon;

- Economic viability; and

- Maximum reactivity

The natural >90% kaolinite content of Toondoon kaolin feedstock and simplified processing give AusPozz™ a competitive advantage with respect to these three key properties and offer tremendous decarbonisation opportunities for the construction industry.

Independent Concrete Trials

In April 2025, Zeotech engaged an independent concrete expert to thoroughly evaluate AusPozz™. The company has conducted all concrete testing to meet Australian Standards at NATA-accredited laboratories across a wide range of concrete mix design applications, achieving impressive results.

- Results demonstrate that AusPozz™ can replace up to 40% of General Purpose (“GP”) Cement and Limestone Type (“GL”) Cement binder in concrete and improve product performance;

- Concrete strength gain of approximately 50% achieved with AusPozz™ when used to replace 20% of GL Cement (56-day MPa);

- AusPozz™ enhances concrete performance, enabling a significant reduction in total cement binder, thereby accelerating a lower total embodied carbon for concrete;

- The cementitious binders in concrete are the most expensive components in terms of cost and carbon intensity; therefore, reducing binder use can yield positive economic and environmental outcomes;

- AusPozz™ can significantly reduce concrete shrinkage compared to GP Cement and GL Cement controls, which is a desirable technical and commercial advantage;

- AusPozz™ can replace silica fume in concrete, supporting significant cost reductions and handling improvements; and

- When used in optimised designs for large volume concrete applications such as wind farms and deep foundation pilings, AusPozz™ can eliminate the challenging issue of heat differential.